Partnering for Rollshop Success: Customised tools for the toughest roll-shop challenges

Formtool Precision Engineering is based in Auckland, New Zealand. First established in 1972, the company has been owned by directors Rodney and Iris Ewing since 2003.

We employ highly experienced staff, many with a lifetime of experience in precision engineering. Using only the highest quality tool stock combined with our experience in the specialised field of tool grinding, our cutting tools frequently outperform and outlast our competitors’ tools.

The company has built its reputation on supplying custom-ground, precision tooling to the steel processing and other manufacturing industries. The workshop is equipped with high precision CNC machinery and the latest measuring equipment to ensure correct profiles and cutting angles are produced.

We manufacture any quantity from prototypes to large production runs.

The key foundations of our business are to provide quality and service; meet customer timeframes; help customers to resolve issues by sharing our extensive knowledge and adapting to customers individual requirements.

Formtool makes tools which last, first time, every time.

Flexible and Agile: Our Approach to Innovation

Our fast turnaround and international courier service means we can deliver tools to your door within a very competitive timeframe.

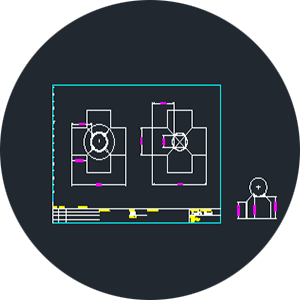

Our workshop, equipped with the latest CNC lathe and CNC mills, cylindrical grinders, surface grinders and tool and cutter grinders, enables us to manufacture high precision components and replacement parts to tight tolerances.

We offer either component manufacture to your CAD drawings or sketches or full turn-key product development.

We pride ourselves on working closely with our customers to create product that’s fit-for-purpose, helping to maximise customer value - through innovative use of machinery and keeping up to date with the latest trends and developments in the steel mill industry.

We have a worldwide customer base who trusts and values Formtool augmented products.

We pride ourselves on accuracy and delivering great value product on time and at a fair price.

Formtool Precision Engineering is based in Auckland, New Zealand. First established in 1972, the company has been owned by directors Rodney and Iris Ewing since 2003

Reliable Solutions, Trusted Performance: Formtool's Commitment

“Choosing Formtool means unlocking a world of advantages:”

Expertise:

Access a dedicated team of trade experts, specialized manufacturing techniques, and a rigorous QA department. Your success is our expertise.

Transparent Communication:

We believe in open and honest communication. You can count on us for meticulous documentation and proven quality control processes every step of the way.

Industry Experience:

Lean on our deep industry knowledge in the steel mill sector. We have extensive experience, and we're excited to share our insights with you.

High-Quality Materials:

We source only the finest European-made materials, such as PCD, PCBN, and Carbide, ensuring that your tools are of the highest quality.

Longevity Assurance:

Our commitment to quality includes using case-hardened materials, guaranteeing the durability and longevity of your tools.

Scalability:

Whether your needs are large or small, we have the flexibility to handle production runs of any size.

Reliable Timelines:

We take our commitments seriously. Expect us to consistently deliver on the agreed-upon timelines, so you can plan with confidence.

Compliance:

Trust us to navigate the complexities of compliance. From tender processes to contracts, pricing arrangements, shipping, and legal documentation, we've got it covered.

At Formtool, we're not just a supplier; we're your dedicated partner. Our unwavering dedication to excellence and customer-centric approach set us apart. Count on us to provide top-quality solutions tailored to your specific needs. Join us on this journey to success.

Building on our history of Design & Innovation

Formtool - Our Journey

1972

Formtool Engineering was founded by two skilled tool makers who introduced one of the first Diamond grinding wheels for carbide grinding in New Zealand.

1970

Formtool successfully devised a new process to manufacture wire rope swages.

1980

One of Formtool's engineers built the Beattie Clubman, a successful racing car on tracks around New Zealand.

2003

Formtool Engineering was placed under the ownership of directors Rodney and Iris Ewing

2004

Formtool Engineering successfully fixed asymmetries in the Notching Tools

2005

Formtool becomes a solutions manufacturer for the Steel Industry. Product offer includes: PCD, CBN & Carbide Notching, IMD Marking, Tool Holders & Arbours & Bases

2006

Formtool Engineering goes global, with our products are being used worldwide.

2022

Celebrating 50 Years of Business Excellence. Proudly manufactured in New Zealand

2023

Formtool’s in Germany Proud to be part of the largest Steel Mill industry event - METECH

2024

Formtool’s Tool Holder can hold different thickness size inserts, saving setting up time when

rolling various size rebar.

Environmental &

Sustainability

Making a difference, globally

We have built our Rollshop consumables business by being able to have open communication and working closely with our customers to meet their targets and to help them overcome their challenges.

We research and work with different steel mills to ensure continuous improvement and innovation of the products and services to our clients.

We manufacture Rollshop Consumables for our customers throughout Australia, Canada, Egypt, Germany, Korea, Kuwait, Malaysia, Morocco, New Zealand, Oman, Qatar, Saudi Arabia, Turkey, UK, United Arabic Emirates, USA, Vietnam and more.

Low Carbon Producer

In our view, our tool steel products are pretty clean and green. Our tools are crafted in New Zealand with 80% renewable electricity from hydro, wind and geothermal resources. Our production processes meet New Zealand’s environmental requirements and global quality standards.

Environmental & Sustainability Corporate Statement

Embracing our role in facilitating consistent, high-quality rebar production for the steel mill industry, sustainability takes center stage in our ethos. Right from inception, we shoulder the responsibility of sustainable manufacturing.

Our commitment reverberates through our practices – our machines are meticulously calibrated for optimal product sizing, eliminating energy wastage. Regular maintenance ensures minimal environmental impact. We are committed to curbing our carbon footprint, bolstering recycling efforts, and optimising energy efficiency. The beauty of steel and carbide lies in their infinite recyclability, a testament to their enduring strength and properties.

Social Reponsibility

Our dedication to social responsibility permeates our operations. By reimagining systems and processes and by integrating environmentally conscious manufacturing practices and online systems, we shrink our carbon footprint.

We staunchly believe in a diverse, equitable, and inclusive community. Our team is a tapestry of cultures and backgrounds united by a common purpose. Through comprehensive training, we strive to craft a self-sufficient, sustainable society, contributing to a brighter future for all.

Reach out to Formtool Engineering today to embark on a journey of innovation, excellence and responsible manufacturing.

Mission, Vision and Values

Mission

At Formtool, our mission is to be the leading supplier of high-quality tools and services to the steel mill industry. Through unceasing R&D, unwavering product innovation, meticulous manufacturing, and seamless product supply, we forge a path of reliability and excellence.

Vision

Our vision is to stand as the preeminent choice for best-in-class Steel Mill consumable products and services. We aim to be your preferred partner, propelling you towards operational excellence and success.

Values

integrity:

Our foundation is based on honesty, transparency, ethics, and fairness. With a legacy spanning over 50 years, Formtool has garnered unwavering trust from individuals and industries alike.

Passion:

We are fervent advocates of our industry, fostering relentless innovation and enhancement. Our commitment extends to delivering supreme value, quality, and service, nurturing enduring relationships with our esteemed clientele.

Our Directors

RODNEY EWING

Managing Director

Rodney was born in New Zealand and

trained as a saw doctor in the woodworking

industry, learning the art of sharpening both

high speed steel and tungsten carbide

cutting tools.

He left New Zealand to gain more

experience in the tooling & sharpening

industry, and met his future wife Iris while in

London, England. Returning to New Zealand

he worked in a tooling shop where he was

responsible for maintaining and developing

cutting tools for their ferrous and non-

ferrous products. Rodney then took on a

workshop managers position in the tool

sharpening industry.

Rodney purchased Formtool Engineering in

2004 and has built up the company by

providing high quality tooling and

engineering services to niche industries.

Rodney is an open & outgoing person, and

being a problem solver he enjoys engaging

with clients to solve their issues and to make

tools that are fit for purpose.

IRIS EWING

Financial Director

Iris was born in Germany and had a background in both sales and business administration before emigrating to New Zealand in 1992. Iris' experience in procurement, data analysis, and business management helps her to manage the financial and administrative roles at Formtool. Her extensive procurement and logistics experience ensures overseas shipments, product and documentation, are in line with customers' requirements, custom regulations & laws.

Testimonials

Our customers value our products and services.

At FORMTOOL ENGINEERING SERVICES LIMITED, we supply high-quality, reliable Rollshop consumable tools that our clients come back to again and again. We are a top solution manufacturer for rebar notching consumables & supplies, with decades of experience behind us. We work with our customers to meet their specific goals.

Let us look at some feedback we have received from our customers:

These are just some of the comments we have received, and we like to say thank all our loyal clients. Formtool has been serving the steel mill industry for decades. If you like to find out more contact us now to find out how we can assist you.